Turning the wooden “Burka” amplifier

with Michael Hamilton-Clark:

I decided I’d have a go at making a wooden amplifier along the lines of the YouTube video for which John Spitters sent the link for posting on our website earlier in the week.

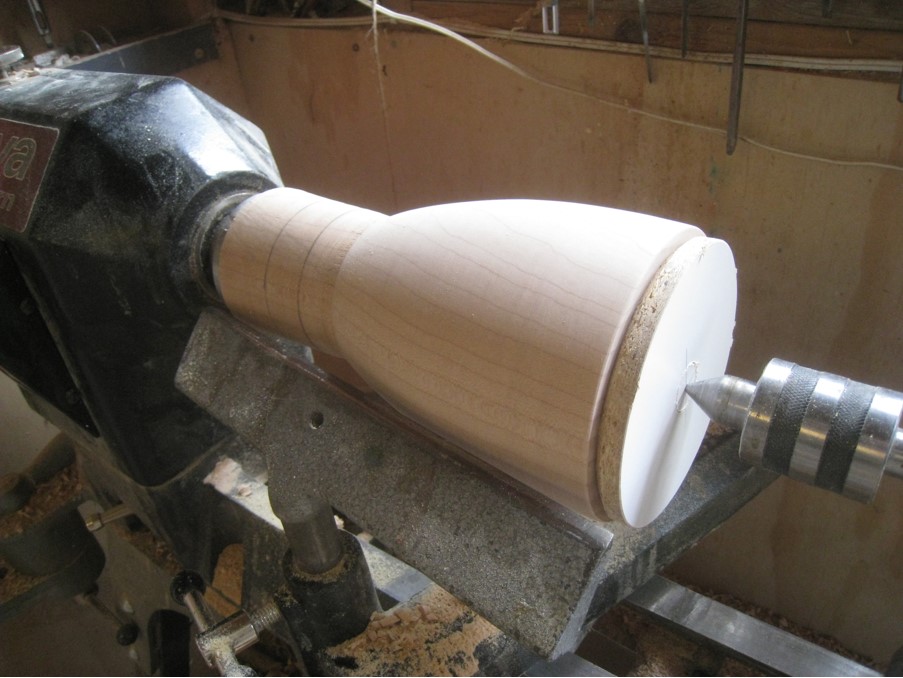

Though there were no actual drawings shown, the mention of the two basic dimensions of a 13cm diameter and 20cm overall length along with the various views during the video were enough to draw a working profile for which I used a 5-in diameter and 8-in overall length.

I went to Bow River Woods and bought a piece of AA Maple 5.5in square and 10-in long. I mounted this on a 4-in faceplate and turned it down to a 5-in cylinder. I had decided that the internal depth would be 7-in and I hollowed out a cone then used my hollow form scraper to make a bit of an outward curve. For checking I used a cardboard profile cut to ¼-in inside my working profile.

The outside was then turned starting at the outer end using check measurements every inch, taking calipers measured across the working profile. In this way a nice even shape and ¼-in wall thickness were obtained.

Before fining the end down I made the cuts for the phone slot. I decided the back cut should be ½-in in front of the end, this to get maximum amplification length. Then it was time to finish the end, sand, and apply a walnut oil finish.

Next the two feet were made. With the cone laid on the cutting table, I determined these needed to be 1.5-in long. Once they were installed, I took the phone with music playing and placed it in the slot.

Disaster! Whilst the amplification was impressive, the cone was not stable and rolled to one side or the other…Why???….Investigation showed the slot to hold the phone was behind the contact point of the cone with the table…… so the weight of the phone with the distance back gave enough leverage to lift the front and hence the legs were off the ground…. I tried 2-in legs, but there was still a tendency to roll. I decided some weight and lateral spread was required up front so I took a piece of 1.5-in square Oak 6-in long and having carved the top out to match the cone slope, screwed it in place. The result was total stability. My grandson was much taken with the whole idea, and if he’ll use one instead of earphones, it’d be a good thing, so I plan to make another one for him – and this time I’ll make sure the phone slot is bit forward of the contact point, then there should not be any uplift due to the weight of the phone….and the slot will be wider across so the phone can go further in, thus lower down and reducing the tendency to cause rolling.

Michael Hamilton-Clark